Product

Home – Product

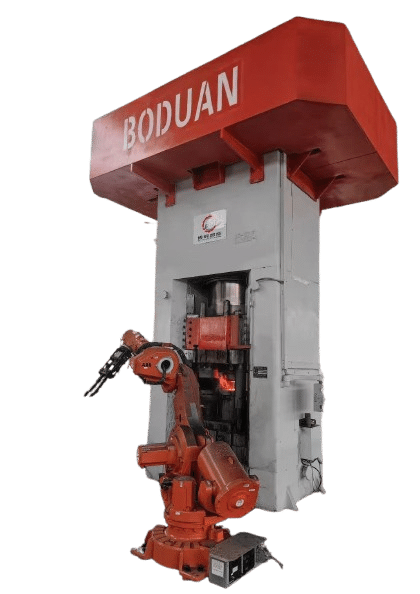

For Forging Industry

Electric Screw Press

For Forging Industry

Direct Drive Press

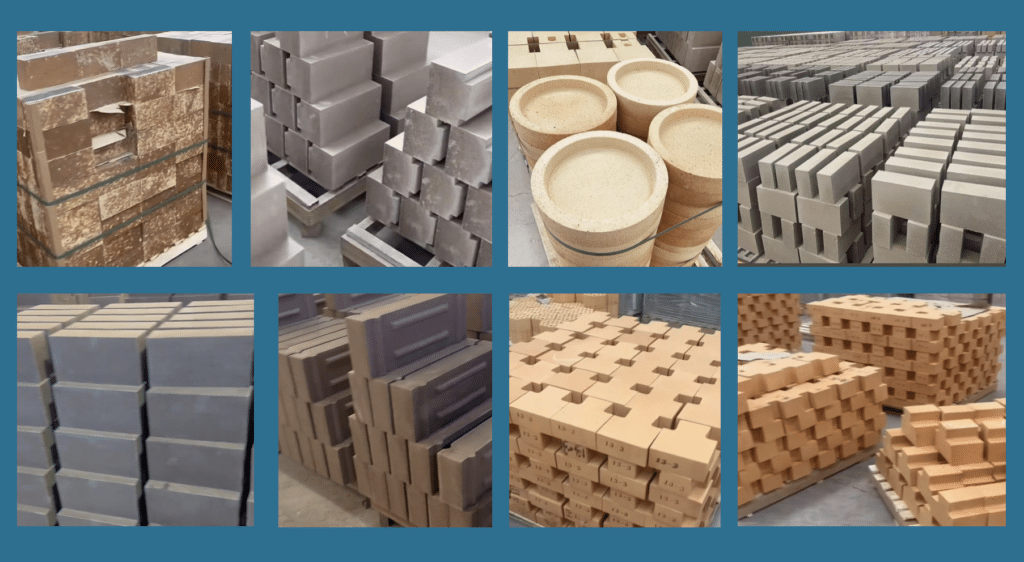

For Refractory Industry

Electric Screw Press

Years Experiences

How We Work

We Prioritize Your Success

With 12 years of experience, we provide efficient and reliable forging solutions tailored to your needs.

01.

Consultation & Assessment

We analyze your production needs and offer expert advice to enhance efficiency.

02.

Custom Solutions

Get the right press machine for optimal performance and cost-effectiveness.

03.

Installation & Support

We ensure smooth setup, operator training, and ongoing technical assistance.

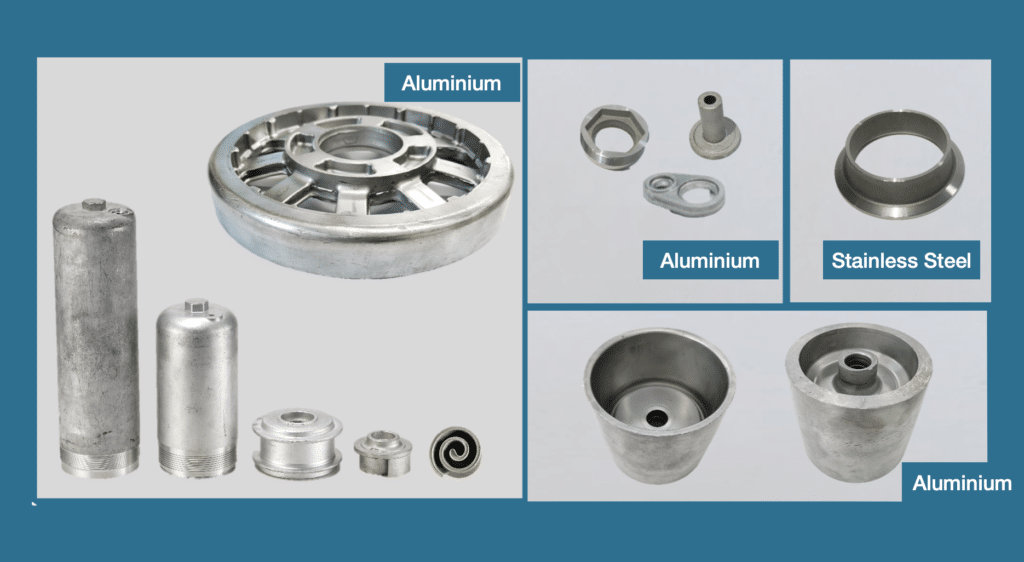

Application of The Press Machine

Frequently Asked Questions

Got questions about our press machines? Find answers here on electric screw, servo direct drive, and refractory solutions—straight from the experts at Boduan

What is an Electric Screw Press Machine, and what are its main applications?

An Electric Screw Press Machine is a high-efficiency forging equipment widely used in industries such as automotive parts manufacturing, aerospace components, and refractory materials production. It offers fast, stable, and repeatable precision forging, making it ideal for heavy-duty parts and high-volume production.

How does a Servo Type Direct Drive Press Machine improve energy efficiency?

Servo Type Direct Drive Press Machines utilize advanced servo motor technology, which provides high energy efficiency, low noise, and minimal vibration. This technology reduces power consumption significantly while maintaining high precision and performance, making it a cost-effective solution for high-precision forging tasks.

Can BoDuan's press machines handle refractory materials production?

Yes, BoDuan’s Electric Screw Press Machines are specifically designed to handle refractory materials production. They provide consistent pressure and precision, ensuring high-quality output for refractory products used in high-temperature environments, such as furnaces and kilns.

What customization options are available for BoDuan’s press machines?

BoDuan offers customized solutions, including tailored machine sizes, auxiliary components, and integrated production lines. With our in-house casting workshop, we can design and manufacture press machines to meet specific client requirements, ensuring optimal performance for unique applications.

What after-sales support does BoDuan provide for its press machines?

BoDuan provides comprehensive after-sales support, including installation, operator training, and maintenance services. We also offer quick access to spare parts and responsive technical assistance to minimize downtime and ensure smooth operations.

Why should I choose BoDuan's press machines over competitors?

BoDuan combines over 12 years of industry expertise with state-of-the-art technology to deliver reliable, high-performance press machines. Our machines are backed by international certifications, and we offer end-to-end solutions, from customized equipment to ongoing support, ensuring maximum ROI for our clients.

How can automation improve efficiency in a forging production line?

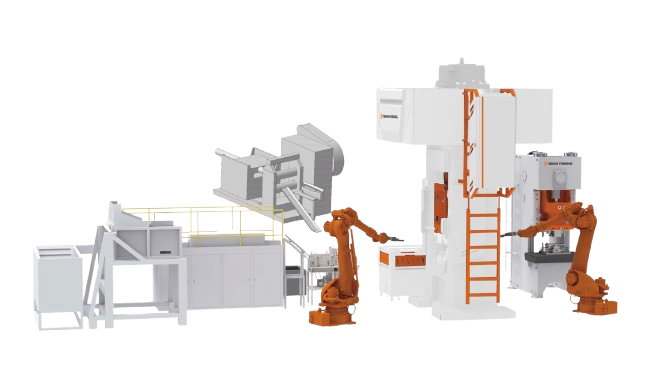

Automation streamlines forging processes by reducing manual labor, minimizing errors, and increasing production speed. Automated systems, such as robotic arms and conveyor systems, ensure consistent quality and allow for 24/7 operation, significantly boosting overall efficiency.

What types of robots and manipulators does BoDuan offer for forging automation?

BoDuan provides a range of advanced robotics and manipulators, including Six-Axis Robots from top brands like YASKAWA, FANUC, ABB, and KUKA, as well as specialized forging manipulators such as Two-Axis Coordinate Forging Manipulators, Three-Axis Swing Arms, and Dual-Arm Walking Beam Forging Manipulators. These solutions are designed to enhance precision, flexibility, and productivity in forging operations.

Transmission Principle of

Electric Screw Press

Figure 4-3-1: Transmission Principle Diagram of Electric Screw Press – a) ~ e) Ring Stator, f) Arc Stator, g) ~ i) Electromechanical Transmission; 1. Stator, 2. Rotor, 3. Screw, 4. Nut, 5. Slide Block, 6. Motor, 7. Gear Transmission Mechanism.

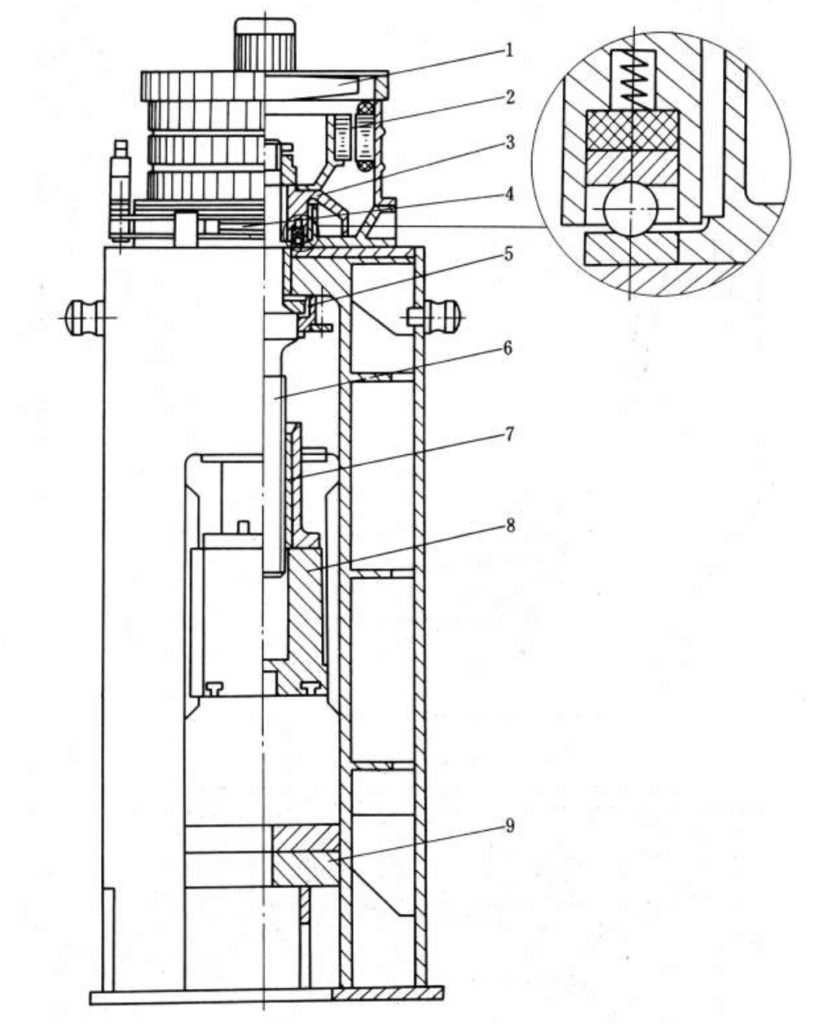

Diagram of Electric Screw Press

BD80 Electric Screw Press: 1. Fan, 2. Motor, 3. Flywheel, 4. Brake, 5. Heel Block, 6. Main Screw, 7. Main Nut, 8. Slide Block, 9. Machine Body

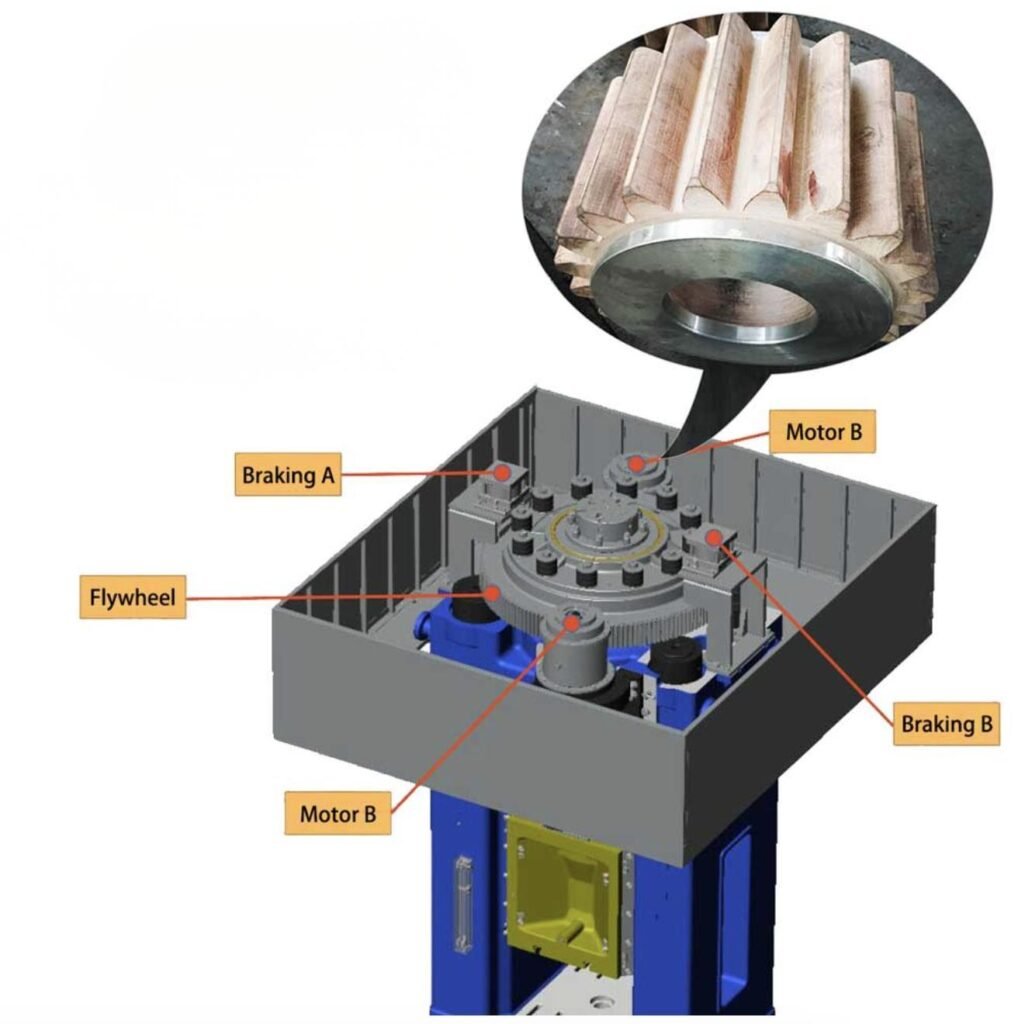

Diagram of Servo Direct Drive Press

BD90-EPZ Series direct drive press feature high-speed, low-torque motors, easy maintenance, and replaceable components. Continuous innovation ensures superior efficiency, solidifying our leadership in the press machine industry