Electric screw press machines are designed to provide the accuracy and consistency necessary for manufacturing high-performance refractory materials.

The production of refractory materials, such as firebricks, kiln linings, and heat-resistant components, requires extreme attention to detail and precision. This is particularly true when forming materials that must withstand high temperatures without breaking down. Electric screw press machines offer a solution by providing repeatable, precise pressure, ensuring consistent product quality and improving overall production efficiency.

Why is Precision Critical in Refractory Material Manufacturing?

Refractory materials need to maintain structural integrity at extremely high temperatures. Inconsistent pressure during manufacturing can cause weak points in the material, reducing its ability to withstand thermal stress. Electric screw press machines deliver highly controlled, consistent pressure to ensure uniformity and strength in refractory materials.

Precise pressure control is essential in the refractory materials industry to ensure that products can endure the extreme conditions they are designed for. Electric screw press machines provide this precision, making them ideal for manufacturing high-quality refractory products.

Press machine in refractory industry

The refractory materials industry is highly specialized, producing products used in environments exposed to extreme heat, such as furnaces, kilns, and reactors. Whether it's producing firebricks, heat shields, or other refractory products, these materials must have uniform strength and density to perform as expected under high-temperature conditions.

Inconsistent pressure during the forming process can lead to uneven density or weak spots in the material. This compromises the material's performance and durability, potentially leading to failure in high-temperature environments. Electric screw press machines, however, offer precise, repeatable force control, ensuring that each product is made with the same level of pressure, which results in consistent density and strength.

How Electric Screw Press Machines Ensure Consistency in Refractory Materials

Electric screw presses use servo-controlled motors that provide real-time feedback, adjusting the amount of force applied based on the material's needs. This helps achieve a uniform result every time, ensuring that the material’s density is consistent and meets the required standards for heat resistance. In the refractory materials industry, this uniformity is crucial. Products with uneven density may fail to provide adequate thermal protection or could break down under stress.

Key Features of Electric Screw Press Machines for Refractory Material Production

Problem: Selecting a press machine for the refractory industry can be challenging, as the equipment must handle high forces and meet precise specifications.

Agitation: Poorly designed machines can result in inefficiency, high operational costs, and subpar product quality.

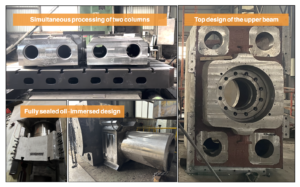

Solution: Electric screw press machines with features like servo motors, oil-immersed systems, and high force capacity are perfect for handling the high-stress demands of refractory material production.

Electric screw press machines with advanced features, such as servo motors, split body designs, and oil-immersed lubrication systems, provide optimal performance in the refractory materials industry.

Press machine in operation, worker overseeing the process

Electric screw press machines come with various features tailored to meet the exacting requirements of the refractory materials industry. Some of the most important features include:

Key Features

| Feature | Description | Benefits |

|---|---|---|

| Servo Motor | Offers precise control over the force applied during the press cycle. | Ensures consistent pressure, improving material quality and reducing defects. |

| Split Body Design | Enables quick access to the press components for maintenance and repairs. | Minimizes downtime and maintenance costs, ensuring continuous operation. |

| Oil-Immersed System | The screw and nut are immersed in oil for continuous lubrication. | Extends the lifespan of the press, reduces friction, and ensures smoother operation. |

| High Force Capacity | Built to handle the extreme pressures required in refractory material production. | Meets the force requirements for shaping dense, high-strength refractory materials. |

| Energy Efficiency | Servo motor-driven technology reduces energy consumption. | Lowers operational costs and reduces the environmental footprint. |

Simultaneous processing of two columns

Precision Process of Screw and Copper Nut

These features allow electric screw press machines to handle the high-stress requirements of refractory material production, ensuring that each product is made with the same level of precision and strength.

How Do Electric Screw Press Machines Improve Efficiency in Refractory Material Manufacturing?

Problem: Traditional pressing systems can be slow and require frequent maintenance, leading to reduced production rates.

Agitation: The longer machines are down for maintenance or retooling, the lower the throughput and profitability.

Solution: Electric screw press machines offer faster cycle times, less downtime, and more consistent results, which boosts overall production efficiency.

Electric screw press machines improve efficiency by reducing maintenance needs, speeding up production cycles, and ensuring high-quality output with minimal variability.

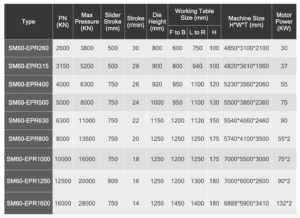

Electric Screw Press For Refractory - Technical Parameter Chart

In the refractory materials industry, efficiency is essential. Traditional press systems, such as hydraulic presses, can be slow to operate and often require frequent maintenance. These delays and inefficiencies can significantly reduce production output, causing plants to miss deadlines and increase labor costs.

Electric screw press machines, on the other hand, offer faster cycle times due to their precise control over the pressure and force applied during each cycle. The servo motor allows for quick adjustments and faster cycle times, which helps increase throughput and reduce labor costs.

In addition, the split body design and oil-immersed lubrication system reduce the need for regular repairs and maintenance. Electric screw presses require less frequent servicing and are designed to run smoothly with minimal intervention. This results in more reliable operations and greater uptime, which boosts overall production efficiency. For refractory materials manufacturers, this improved efficiency means they can meet the increasing demand for high-quality, heat-resistant products without compromising on performance.

Electric screw press machines provide significant advantages for the refractory materials industry, offering precise pressure control, improved consistency, and increased production efficiency. These machines meet the high demands of the industry, ensuring that refractory products are formed with the necessary strength and uniformity to perform in extreme environments. By investing in electric screw press machines, manufacturers can improve their production processes, reduce waste, and deliver high-quality products to meet customer demands.